Gilsonite, also known as natural asphalt or uintaite, is a naturally occurring solid hydrocarbon used to enhance the properties of various bitumen-based materials. Its high carbon and asphaltene content make it one of the most effective natural modifiers in the asphalt industry.

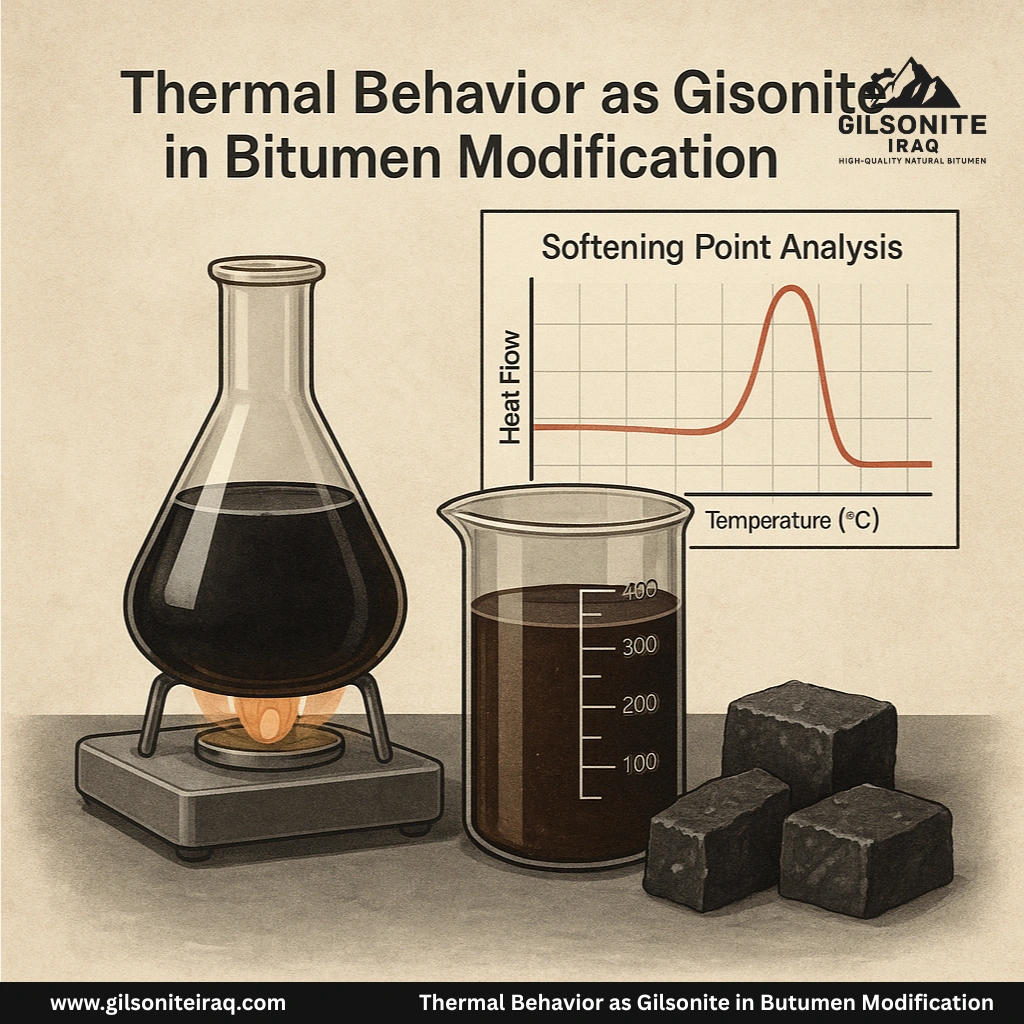

Among the key performance parameters of bitumen, the softening point plays a critical role in determining the temperature resistance of asphalt binders. A higher softening point indicates better resistance to rutting, deformation, and bleeding under high temperatures — essential in hot climates such as Iraq and the Middle East.

This article explores the thermal behavior of Gilsonite, the scientific basis behind its performance, and standardized testing methods used to measure its impact on bitumen.

Understanding the Thermal Behavior of Gilsonite

The thermal behavior of Gilsonite is primarily governed by its molecular composition, consisting of asphaltenes (complex polycyclic aromatic hydrocarbons), resins, and minimal volatile fractions.

When Gilsonite is blended with bitumen, it increases the concentration of asphaltenes and introduces high aromatic carbon rings that provide thermal rigidity and oxidative stability.

In practical terms, pure Gilsonite softens at approximately 160–220°C, depending on its grade and purity. When mixed into bitumen, it raises the mixture’s overall softening point and enhances its high-temperature performance.

This improved performance is attributed to molecular interactions — particularly the formation of stable aromatic networks that resist thermal degradation.

Softening Point Analysis Methods

The most widely accepted testing methods for evaluating bitumen modification with Gilsonite are:

- Ring-and-Ball Test (ASTM D36)

This method measures the temperature at which a standard-sized bitumen sample softens enough for a steel ball to drop a specific distance under controlled heating.

In unmodified bitumen, typical softening points range between 45–55°C. When modified with 10–15% Gilsonite, the softening point often increases to 60–75°C, depending on blending conditions. - Penetration Test (ASTM D5)

Used in combination with the softening point test, it assesses the consistency and hardness of bitumen. Gilsonite addition generally decreases penetration values — indicating a stiffer, more temperature-resistant binder.

Source: ASTM.org

Effect of Gilsonite Content and Particle Size

The particle size distribution and dosage level of Gilsonite are crucial factors in achieving homogeneous blending and stable performance.

- Particle Size:

Finer Gilsonite particles (typically 75–150 microns) ensure better dispersion within the bitumen matrix and avoid localized agglomeration.

Coarser particles can cause uneven melting and reduce homogeneity. - Content:

The optimal concentration of Gilsonite ranges from 5–15% by weight of bitumen.- At 5%, there is a moderate improvement in softening point and viscosity.

- At 10–15%, significant increases in softening point (up to 25°C) and rutting resistance are observed.

- Beyond 15%, workability during mixing and compaction becomes challenging due to excessive stiffness.

Thermal Decomposition and TGA/DSC Analysis

To evaluate the stability of Gilsonite-modified bitumen, researchers often employ Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC).

- TGA Results:

Show that Gilsonite begins to lose minimal volatiles around 300°C, with major decomposition occurring above 450°C.

This indicates a high thermal stability compared to conventional polymer modifiers like SBS (Styrene-Butadiene-Styrene). - DSC Curves:

Demonstrate that Gilsonite enhances the endothermic transition temperature of bitumen, shifting it toward higher values.

Iraqi Gilsonite, in particular, exhibits excellent heat resistance due to its higher asphaltene-to-resin ratio, resulting in a slower thermal oxidation rate.

Source: SienceDirect

Comparative Study: Iraqi Gilsonite vs. Other Sources

Gilsonite deposits from different countries vary in composition and performance. Laboratory analyses show that Iraqi Gilsonite typically contains:

| Property | Iraqi Gilsonite | Iranian Gilsonite | American Gilsonite |

|---|---|---|---|

| Ash Content (%) | 3–6 | 5–8 | 4–7 |

| Carbon Content (%) | 85–88 | 83–85 | 82–85 |

| Softening Point (°C) | 185–220 | 165–200 | 160–190 |

| Asphaltene (%) | 65–75 | 55–65 | 50–60 |

| Solubility in CS₂ (%) | 98–99 | 95–98 | 95–97 |

These results demonstrate that Iraqi Gilsonite has a superior softening point and carbon content, making it ideal for high-temperature asphalt and drilling applications.

Engineering Implications for Road and Roofing Applications

The enhancement of the softening point translates directly into improved field performance:

- In Road Construction:

Gilsonite-modified bitumen shows increased rutting resistance, especially under heavy traffic and hot weather conditions. Roads remain smoother, with less deformation and bleeding. - In Roofing Materials:

The increased softening point ensures that membranes and coatings remain stable under prolonged sunlight exposure, reducing surface melting or sagging. - In Hot-Mix Plants:

Since Gilsonite is thermally stable, it can be added directly into the hot mix without degrading, simplifying the blending process and improving cost efficiency.

Recommended Blending Parameters

| Parameter | Recommended Range |

|---|---|

| Mixing Temperature | 160–190°C |

| Gilsonite Content | 5–15% (optimum: 10%) |

| Particle Size | 75–150 µm |

| Mixing Time | 30–45 minutes |

| Compatibility Additives | Optional (aromatic oil or maltene restorer for better dispersion) |

Conclusion

The thermal behavior and softening point analysis of Gilsonite clearly demonstrate its value as a natural performance enhancer for bitumen.

By raising the softening point, improving thermal stability, and providing superior oxidative resistance, Iraqi Gilsonite stands out as a cost-effective and sustainable solution for road, roofing, and industrial applications.

As global infrastructure projects expand in hot climate regions, the demand for high-performance binders continues to rise — and Gilsonite remains a proven natural choice for long-lasting performance.